Overview

RF and electronic manufacturing capabilities include solder; assembly; thin film substrates and metal fab; automated processes such as pick and place, wire bonding and optical inspection; environmental screening (shock, vibe and temperature); plating and etch; paint; laser seal, and design-for-manufacturing. Some CAES manufacturing facilities also offer MIL-PRF-38534, IPC and NASA Certifications, Nadcap certification for plating, DMEA Trusted Accreditation, anechoic chambers, wedge wire bonding, conformal coating, and clean room operations.

Automated Assembly

Advanced Automated Assembly Solutions

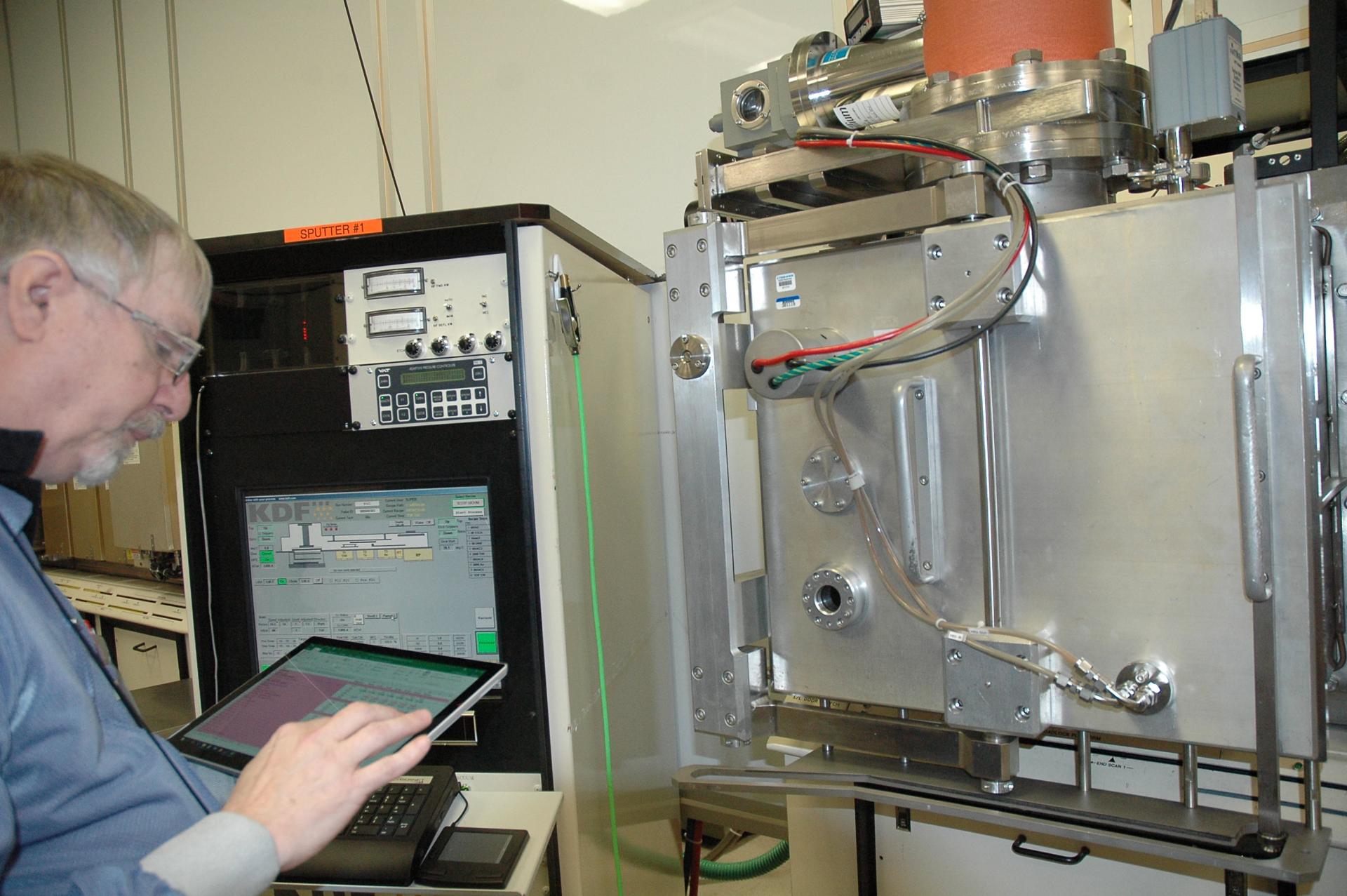

CAES employs highly automated assembly capabilities.

CAES reduces product and program costs with a high level of automation in the assembly processes. Nearly 10,000 modules flow through CAES factories each month.

Partnering with customers to leverage design for manufacturing engineering techniques, CAES factories are capable of complex manufacturing of microwave and millimeter wave assemblies.

Employing automated pick and place, automated wire bonding, automated optical inspection, and robotic material delivery, CAES factories enable programs to reap benefits of volume production.

Autonomous material delivery robots

Networked Factory

At some locations CAES is automating material delivery on the factory floor to improve material flow.

Chip and wire

Automated assembly

RF, MMIC, FPGA & AESA advanced assembly

Production team – collaborative approach

Advanced Packaging

Advanced Microelectronics Packaging, Test, and Modeling

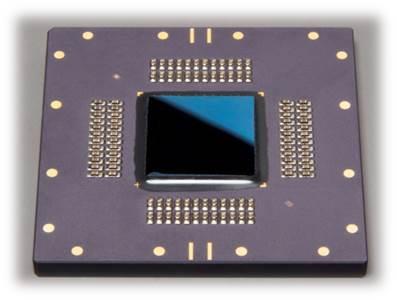

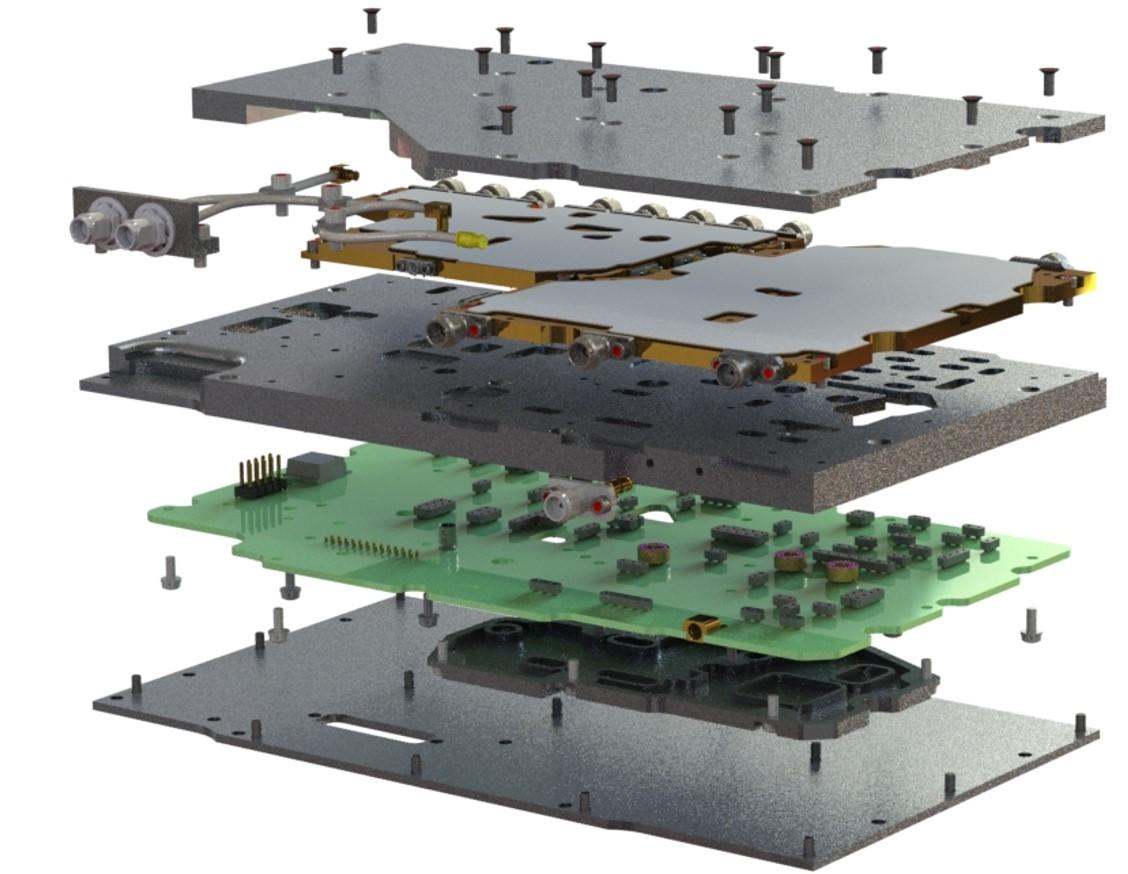

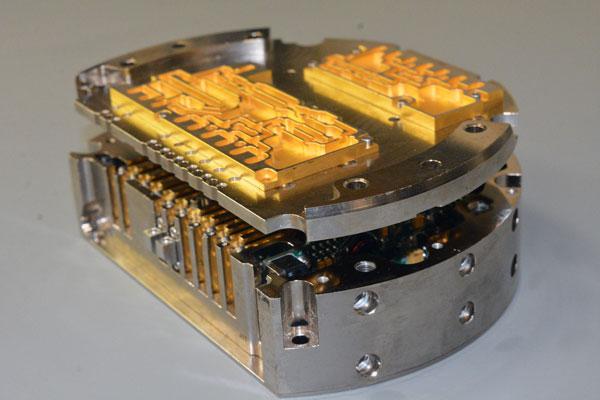

When the highest levels of reliability and performance are needed along with stringent requirements in the areas of size, form factor, power and thermal management, CAES offers advanced microelectronics packaging, modeling and testing solutions.

Building on a heritage of providing custom package solutions for the most demanding aerospace, defense and medical IC products developed at CAES, we have a proven capability to identify, select and design a solution tailored to the unique requirements of your mission. Our flexible engagement model allows us to support a range of services from rapid prototyping of a small number of die for validation and characterization to full volume production in our DMEA accredited trusted facility. Numerous package technology and process flow options are available, ranging from ceramic QML to organic commercial packages.

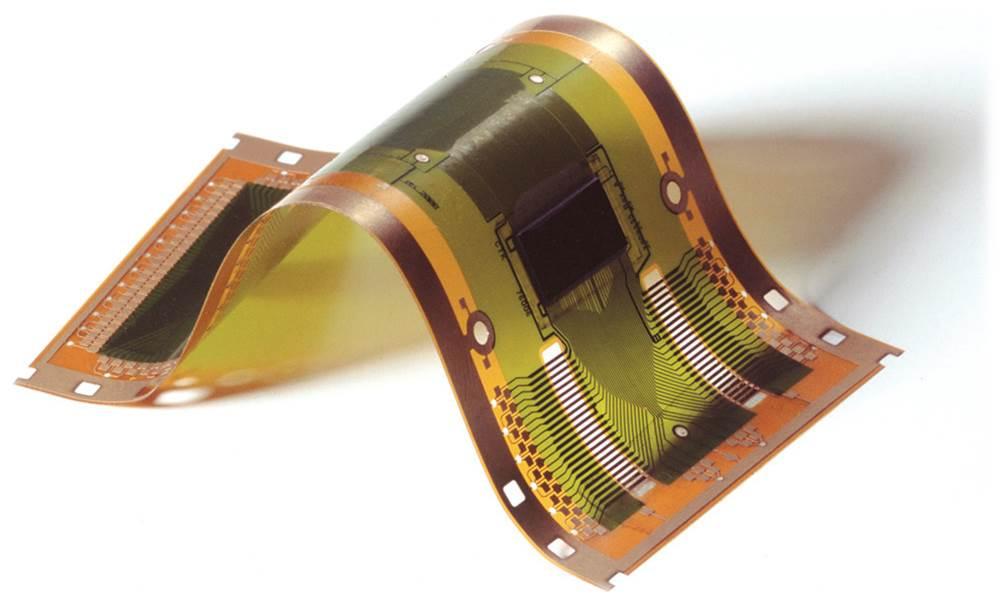

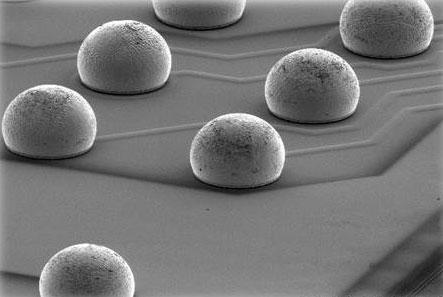

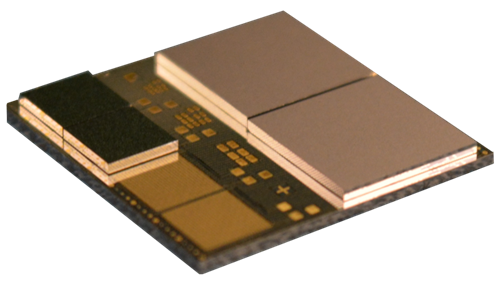

System in Package (SiP) solutions leveraging 2.1D technology to place multiple die in a single package are available to enable smaller footprints, increased performance and the integration of die fabricated in different process technologies or wafer types. A full suite of electrical, thermal and mechanical modeling tools are used throughout the development process to ensure compliance with critical design points and constraints.

Flexible Engagement Model

CAES supports the full spectrum of design engagements ranging from full turnkey to build-to-print using your existing design.

Technology Expertise

Legacy of innovation in high reliability QML, organic flip chip, system-in-package (SiP) technology and form factor optimization while solving critical thermal dissipation and high speed signaling challenges.

Scalable Manufacturing

Support for low volume prototyping and flight quantities to high volume manufacturing of >100,000 per month.

Build to Print/Spec

Build to Print / Build to Spec

Accredited by the United States Department of Defense as a Trusted Source and as a Category 1A supplier for assembly services, CAES offers build-to-print and build-to-specification capabilities, including high-volume automated circuit card assembly.

For customers designing for military, aerospace and other harsh environments, CAES also provides complete COTS and commercial up-screening for high reliability applications that require additional testing and burn-in as well as qualified assembly and test services meeting the requirements of MIL-PRF-38534 Class H and K.

From DC to 40 GHz, CAES provides microelectronic packaging and test solutions for high speed digital, precision analog and RF/microwave devices. CAES carries a range of off-the-shelf inventory and customized options including single board computers; multi-chip, power converter and telemetry modules as well as specialized RF and microwave filters. Our multi-chip module (MCM) packaging technology enables customers to optimize size, weight, power and cost (SWaP) by applying flip chip, chip and wire, chip-on-board, surface mount technology and planar magnetics. In many cases, more than one of these technologies can be combined in a single module.

Electronic Manufacturing Solutions

Electronic Manufacturing Solutions

Offering a full turnkey electronic manufacturing operation complete with testing and coating capabilities in the USA.

CAES has a broad range of well-established Electronic Manufacturing Services (EMS) offerings that support standard product designs and custom microelectronic solutions. Our flexible engagement model, strong collaboration and communication processes allow our customers to outsource everything from circuit card design and assembly to complete turnkey solutions and testing with full ITAR compliance. All CAES EMS sites are fully certified and qualified to assume the most demanding design challenges for customers serving military, aerospace, medical and industrial markets.

CAES EMS solutions provide design, manufacturing, supply chain management and service support for the complete product life cycle to enable our customers to focus on product innovation and differentiation. Our services extend to materials procurement, prototype engineering and qualification, mission suitability analysis, environmental testing and failure analysis, radiation testing, device screening, custom and commercially available plastic packaging and rapid prototype IC assembly.

Certifications & Quality

CAES Lansdale, PA Facility

- ISO9001: 2015 and ISO9100: 2016

CAES San Jose, CA Facility

- ISO9001, revision 2015 compliant without exception

- AS9100 Rev. D (2016), compliant without exception

CAES San Diego, CA Facility

- AS9100:2016 including ISO9001:2015 Multi-Site Certificate

- BAE Special Process Approval for Chemical Film and Paint

- Certificate MIL-PRF-38534 Class-H

- DCMA Authorization: Alternative Release Program

- EVMS Compliance per 32 EIA 748 EVMS Guideline

- Lab Suitability, MIL-PRF-38534 (Manufacturing/Design - to perform on CAES product)

- Lab Suitability, MIL-STD-883 (Environmental Lab)

MW through mmW

Microwave through Millimeter Wave Solutions

CAES’ microwave and millimeter wave manufacturing adheres to established industry and military-specified standards. Workmanship is performed up to and including MIL-STD-883.

CAES offers extensive expertise in the manufacturing of complex microwave and millimeter wave solutions for electronic warfare, radar and other mission-critical needs.

CAES’ manufacturing solution capabilities include thin film substrate manufacturing, package manufacturing, automated pick and place, automated wire bonding, automated optical inspection, hermetic sealing, automated environmental screening, painting and full automated electrical test over temperature.

Assembly and sealing processes are tightly controlled through a combination of statistical process control, first pass yields, incoming inspection, and preventive maintenance. CAES has established failure analysis reporting and corrective action procedures to identify the failures that occur and to determine the root cause.

The specifications leveraged for fabricated boards used in our products meets IPC-6012 class 3 and IPC-6018 class C as appropriate. Mixed solder and hybrid packaging techniques include MIL-PRF-38534 Class H.

Related Products

Support & Contact

Do you need help with an existing product?

Our customer and technical support teams are happy to assist.